| |

The New Era of Laser Cutting:

Where Unlimited Precision Meets Unlimited Possibilities

|

| In traditional metal fabrication shops, the roar of flame cutting, the fumes from plasma cutting, and the constraints of complex moulds are becoming history. Today, laser cutting technology, with its revolutionary precision, speed, and flexibility, is reshaping the boundaries of metal forming. From heavy-duty structural steel to precision sheet metal, and complex tubing, the laser has become a versatile and precise "blade of light." |

| |

|

|

|

| Modern laser cutting solutions have evolved into specialized camps for different needs, collectively building comprehensive flexible processing capabilities: |

| |

Structural Steel Laser Cutting Machine: The Revolutionizer for Heavy Fabrication

|

|

|

Technical Focus

|

| Designed specifically for long-sized profiles like angle iron, channel steel, I-beams, and H-beams. Integrates high-dynamic-precision multi-axis systems capable of completing complex holes, slots, and end cuts on multiple faces and angles of the profile in a single setup. |

|

|

Core Value

|

| Completely replaces multiple processes like drilling, sawing, and punching, solving the century-old pain points of difficult positioning, low efficiency, and poor accuracy in structural steel processing. It is a key piece of equipment for achieving digital manufacturing in construction steel structures, heavy equipment, rail transportation, and other fields. |

|

|

|

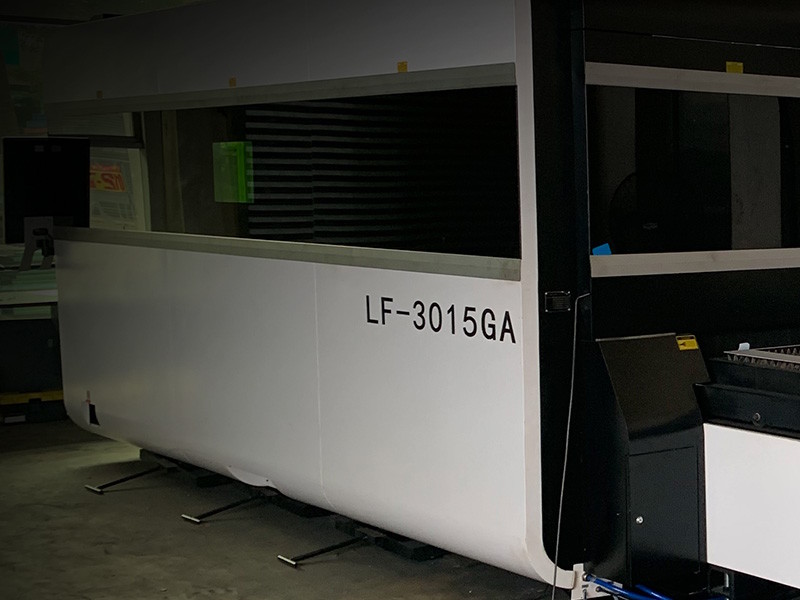

Flat Sheet Laser Cutting Machine: The Benchmark for 2D Cutting Precision

|

|

|

Technical Focus

|

| Encompasses combined sheet-and-tube machines and dedicated sheet metal cutters. Equipped with high-power lasers (often 10kW+), paired with high-speed, high-precision machine tools and intelligent cutting heads, it can perform rapid cutting of any complex shape on metal sheets like carbon steel, stainless steel, and aluminium alloy. |

|

|

Core Value

|

| The extreme efficiency and dynamic performance of fibre lasers, combined with automatic loading/unloading, enable mould-free, batch, and flexible processing of sheet metal. It is the efficiency core for industries like enclosures, construction machinery, and home appliances. |

|

|

|

Tube & Pipe Laser Cutting Machine: The Flexible Expert for 3D Processing

|

|

|

Technical Focus

|

| Specializes in the 3D processing of round, square, rectangular, and profile tubes. Equipped with high-precision chucks, servo rotary axes, and online measurement systems, it can perform angled cuts, holes, slots, and 3D engraving on the surface of tubes and pipes. |

|

|

Core Value

|

| Integrates the functions of multiple machines (sawing, drilling, punching) into one, enabling tubes to be "finished as cut." This greatly drives process innovation and design freedom in industries like fitness equipment, furniture, and automotive parts. |

|

|

| |

|

|

|

Laser Source Revolution

|

| From CO₂ lasers to fibre lasers with higher electro-optical efficiency and lower maintenance, power ceilings continue to break, constantly breaking cutting thickness and speed records. |

|

|

Intelligent Sensing

|

| Integration of capacitive/laser non-contact following, automatic material thickness detection, and auto-focus adjustment ensures the cutting head maintains the optimal distance from the material, effortlessly handling uneven sheets. |

|

| |

Software Empowerment

|

| Advanced CAD/CAM nesting software automatically optimizes cutting paths to maximize material utilization; digital twin and offline programming enable pre-production simulation and zero-downtime preparation. |

|

|

Automation Integration

|

| Seamless connection with automated material storage, logistics lines, press brakes, and welding stations forms a "Laser Cutting Center," becoming a key node in the smart factory. |

|

|

| |

|

|

|

Choose a Structural Steel Laser Cutter when:

|

| Your core material is various structural profiles, processing involves complex multi-face operations, and there are extremely high requirements for the assembly accuracy of structures. |

|

|

Choose a Flat Sheet Laser Cutter when:

|

| Your core material is various structural profiles, processing involves complex multi-face operations, and there are extremely high requirements for the assembly accuracy of structures. |

|

|

Choose a Tube & Pipe Laser Cutter when:

|

| Your core material is various structural profiles, processing involves complex multi-face operations, and there are extremely high requirements for the assembly accuracy of structures. |

|

|

| |

|

|

|

| Leading manufacturers are adopting composite configurations like "Sheet + Tube" or "Sheet + Structural Steel," or even introducing **3D 5-Axis Laser Cutting Machines**. This creates a one-stop flexible platform to handle infinite combinations of materials, processes, and products, maximizing equipment utilization and ROI. |

| |

|

|

|

| Choosing laser cutting is not just about changing equipment; it's about upgrading your entire production logic. We offer comprehensive solutions based on real-world scenarios: |

|

Process Analysis & Customized Proposal

|

| We recommend the most cost-effective equipment combination and automation level based on your material spectrum, product matrix, and production volume. |

|

|

Sample Cutting & ROI Verification

|

| We provide free sample cutting using your actual materials to verify results and economic benefits. |

|

| |

Turnkey Project & Training

|

| We handle everything from site preparation, installation, and commissioning to complete skill transfer for both operators and programmers. |

|

|

Full Lifecycle Service

|

| We provide remote diagnostics, process database support, and consumable services to ensure your equipment maintains peak performance. |

|

|

| |

|

|

|

| Laser cutting is evolving from "replacing traditional methods" to "defining the future." The design freedom and manufacturing efficiency it unleashes make it an indispensable cornerstone of smart manufacturing. Let's explore together how this "precise beam of light" can become the core value-creating unit in your workshop, cutting through metal and opening new dimensions of development. |

|

|

|

|

|

Make Every Cut Flawlessly Precise, Utilize Every Material to Its Fullest.

|

|

|

|

| Explore how laser cutting can enhance your core competitiveness. Contact our process experts for a customized technical proposal and ROI analysis. |

|

| Contact Us |

|

|

|

| |

Why Choose TTMC

|

| The Specialist for Welding, Cutting & Automation |

| |

.png) |

| |

| Expertise & Professional Services |

|

|

.png) |

| |

Cost & Time

Effective |

|

|

.png) |

| |

Systematic

Management |

|

|

.png) |

| |

Value-Added

Services |

|

|

|

| |

Thank You for The Trust

|

| Our Successful Implementation for These Clients |

| |

|

|

|

| |